| Type | Fully Automatic |

|---|---|

| Production | 100 - 250/HR |

| Die Size | All Slipper Die |

| Power Req | 220V |

| Weight in kg( Approx ) | 300 - 700 kg |

Laghu Udyog has garnered its esteemed reputation as a prominent manufacturer and supplier, celebrated for our top-tier Chappal Making Machines. Read more

Enquiry Now

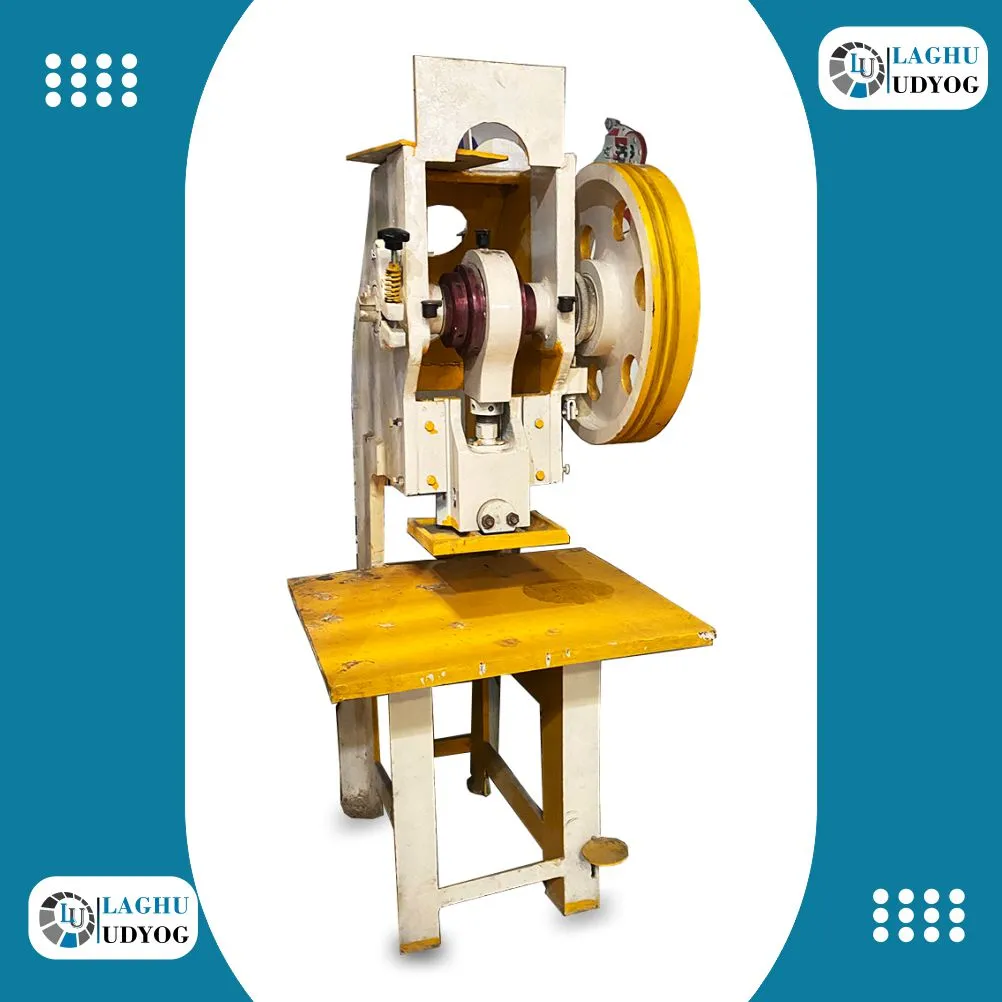

| Type | Manual |

|---|---|

| Production | 100 - 250/HR |

| Die Size | All Slipper Die |

| Power Req | 2 KW Only |

| Weight in kg( Approx ) | 300 - 700 kg |

| Type | Fully Automatic |

|---|---|

| Production | 100 - 250/HR |

| Die Size | All Slipper Die |

| Power Req | 2 KW Only |

| Weight in kg( Approx ) | 300 - 700 kg |

| Type | Fully Automatic |

|---|---|

| Production | 100 - 250/HR |

| Die Size | All Slipper Die |

| Power Req | 2 KW Only |

| Weight in kg( Approx ) | 300 - 700 kg |

| Type | Manual |

|---|---|

| Production | 100 - 250 KG/hr |

| Die Size | All Slipper Die |

| Power Req | 220V Only |

| Weight in kg( Approx ) | 300 - 700 kg |

In today's eco-conscious world, the chappal making machine plays a crucial role in promoting sustainability. By optimizing resource utilization and minimizing waste generation, the machine contributes to a greener manufacturing process. With the advancement of technology, the slipper making machine has transformed the traditional way of crafting slipper. It brings efficiency and precision to the production line.

The chappal making machine in Varanasi boasts a sophisticated design that streamlines the manufacturing process. Through a series of automated steps, raw materials such as rubber are expertly molded and shaped into stylish and durable chappal. This innovative technology has revolutionized the industry, allowing for increased productivity and consistency in the final product.

Slipper making process involves cutting out patterns, assembling using adhesives and stitching of the desired design from the chosen material.

As the demand for stylish and comfortable slipper continues to rise, the chappal making machine in Varanasi stands at the forefront of innovation in the industry. Its advanced technology and efficient operation pave the way for the future of chappal production, offering endless possibilities for manufacturers to create exceptional products that resonate with consumers worldwide.

Fully Automatic Slipper making machine in Varanasi represents a groundbreaking advancement in slipper manufacturing. Its precision, efficiency, and sustainability make it a valuable asset for manufacturers looking to stay ahead in the ever-evolving market. Embracing this technology not only enhances production capabilities but also contributes to a more sustainable and environmentally conscious industry.